Steve Bochan's collection

Steve's

interest

in Standard Electric equipment is pretty much like mine, in that he's interested

in the "newer" (1950-1960) stuff. He collects AR-2/AR-2A master and slave

clocks and has quite a collection and test lab going! Like most collectors

of this equipment, Steve has gone "a little crazy" in obtaining clocks for

his collection.

|

This is

my Standard Electric AR-3 date stamped "October, 1939" on the back. I won

this clock in an Ebay Auction and it came to me with the original AR-3 movement,

original three wire terminal strip above the movement and a dull brown painted outer rim I changed the movement to an AR-2 so that it could run on my AR-2A system I also sanded off the old scratched brown paint from the outer rim and cover, then primed it with a Rustoleum Primer, followed by a generous coating of Black High Gloss Enamel. It works perfectly and looks beautiful in the kitchen. Also, I was able to quiet down the impulse movement a bit by insulating the back cover with some carpet strips I had left over when I had the house built. I was told that the clock originally came from a train station in Pennsylvania, but wouldn't swear on it. Hands and clock face are the originals. |

|

This wooden rimmed

Standard Electric Clock was also won on an Ebay Auction from a nice woman

in Colorado whose dad used to work on these at a school. The time frame

for this clock is the 1940's -- I like the Roman Numerals because I just

haven't seen them that much on the usual Standard Electric clocks.

The impulse movement

was an original straight impulse (no correction), so I couldn't use it on

my AR-2A system as it was. American Time & Signal told me they

could not fit an AR-2 movement onto the clock because the original hands

were a problem. So, I decided to simply put a battery movement in

it and stay with the original hands and clock face.

It hangs on the third

floor of my home in the Master Suite in a domed part of the ceiling and

looks terrific there.

|

|

Here's one you're sure

to recognize. It's one of the large 15" AR-2 Standard Electric Clocks

that I got on my visit to Massachusetts earlier this year when a school

was throwing out their system.

This clock hangs in

my garage and is part of my AR-2A system. I changed out the original

Lucite cover with a glass cover because it makes the clock look better,

in my opinion.

Ed. Note: Steve gave me a clock identical to this one from the same school. |

|

Here's one of the AR-2A

master clocks I retrieved from a recent visit to that school in Massachusetts

that was getting rid of their system. With the help of my friend Gary

Kronberg of Standard Electric Technologies in Richmond, Virginia, this master

clock works like a charm. It keeps perfect -- and I do mean perfect

-- time. Gary replaced a few of the original parts for me (the worm

shaft was slipping because it was wearing down) and he showed me how to

adjust the timing cams inside.

|

|

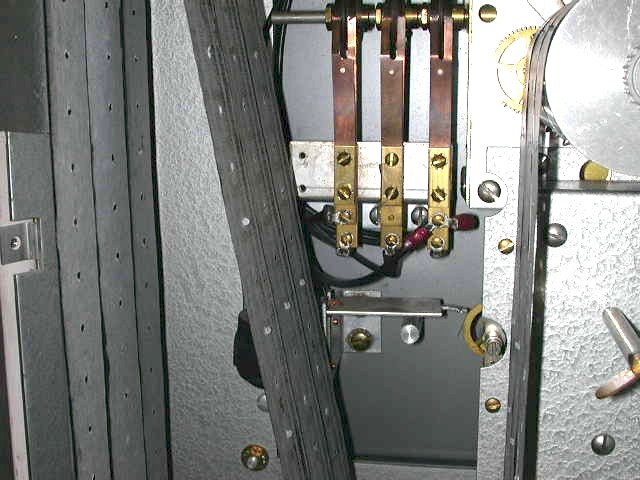

This shows the inside

of my AR-2A Master Clock with three threaded ribbons and the timing cams

in the background.

|

|

As you know, on my trip

to Massachusetts this past fall (2002), I retrieved a bunch of old

Standard Electric Clocks near the Springfield area where the original plant

used to operate. These clocks were being thrown out by a school in

Amherst and I brought them back to Virginia to try and recondition and work

on them one at a time. (Many just needed slight adjustments.)

I saw the picture of

the old testing boards at the Standard Electric plant in Springfield, Massachusetts

on your website, and came up with a similar idea for testing the clocks

I retrieved from Massachusetts. In my garage, I have a total of four

test boards capable of handling 12 AR-2 clocks a piece. All 48

slaves run off of the AR-2A Master Clock in my garage and make quite

a racket when they're all operating :-)

Each clock has

been cleaned, lubricated, tested, rims removed and repainted, clock

faces and hands cleaned and reconditioned, and then run for at least

168 hours continuously to make sure there are no problems with them. I'll

probably end up selling them off to a small business or plant since they

look almost new. This has been a 'learn by doing' project.

|

|

Once again your website

has been a great source of information relative to these slave clocks and

their histories. One of the items you have a link to is the Mumford

Slave Driver, and I am including a picture of the one I use on my workbench

in my garage when testing each AR-2 clock individually.

I cannot say enough

good things about Bryan Mumford and his attitude. He and I had been

corresponding a lot after my trip to Massachusetts, and he was intrigued

by the way the AR-2 slave clock worked, especially with the corrective coil

and the 48-volt charge the master supplied each hour on the 60th minute.

Bryan actually created what he called the "fancy slave driver" for me so

that I could simulate field conditions when testing the AR-2 slave clocks

on my workbench.

His timing chip is

extremely accurate and he supplies two 24-volt transformers for the purpose

of regular impulsing, as well as for the hourly corrective impulse every

60 minutes. It works great (each impulse is clean) and I would

strongly recommend anyone that works on Standard Electric slave clocks to

seriously consider contacting Bryan for one of these for their testing purposes.

As you can see from the picture, they are small and run off of four AA batteries.

There is a way to manually impulse both the minute and hourly corrective

functions by simply pressing a button.

The great thing about

this is you don't need a big clunky old master clock to run a slave clock

you may want to test -- you can use this convenient driver anywhere.

Can you imagine if the Standard technicians had this device in the '60s,

'70s or '80s?

|

|

And last but not least,

here is that 10" clock you sent me a while back. It is part of my

AR-2A system and hangs in my office downstairs.

|

|

Have you ever seen

anything so ridiculous? :-)

The Master on the

left is an AR-2A and is one of the ones I obtained on my Massachusetts trip

in September; the one in the center is also an AR-2A and is the one currently

running my system and the one on the right is a GR-C Master for the GR-C

24v synchronous square clocks that John was getting rid of in Indiana.

The GR-C has a number

of micro switches and other upgrades on the power supply that the AR-2A

doesn't have (micro reset switches, an indicator light that tells when the

power is on, etc.)

|

|

|

This is what my garage looked like after my trip to Indiana. The GR-C slaves are below the test boards (on the floor). |

|

The hourly

correction works, sort of. Very strange. Gary discovered that the 12-hourly

correct micro switch is bad and there are a number of other adjustments that

still need to be made before the GR-C Master is where it should be. |

|

I had

asked Steve to take a picture of the drop fingers in his master clock so

I could compare them to mine. Thought I'd share this picture as well. |